VIKING INDUSTRIES

We redesigned Jakarta Murugan Temple’s website with an elegant and user-friendly interface, enabling seamless online pooja bookings, donations, and event registrations. This digital transformation improved visitor management, enhanced transparency, and increased temple donations by 4x

Overview

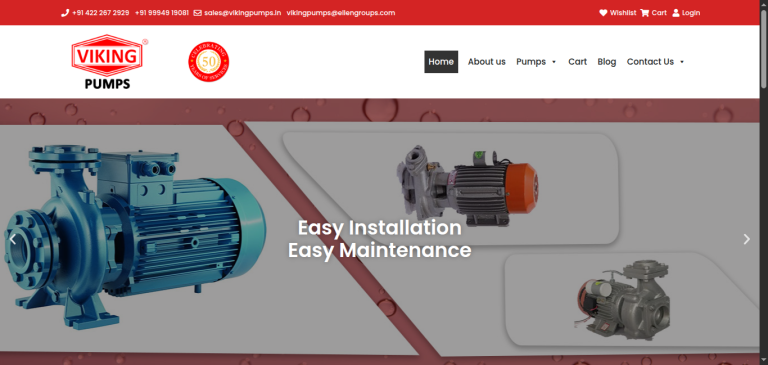

Viking Industries & Pumps required a unified digital and operational system that could manage both their internal manufacturing processes and their customer-facing digital presence. The project involved implementing Odoo ERP to handle production, inventory, costing, procurement, and accounting, while also improving their website structure and content to better showcase products, capabilities, and industry expertise.

Problem Statement

Viking Industries & Pumps was operating with disconnected systems, manual spreadsheets, and outdated digital tools, which led to inconsistent inventory data, inaccurate production costing, slow stock request/issue processes, and limited visibility into real-time operations. The website was also outdated, lacking clear product information, structured content, and strong calls-to-action, making it difficult for customers to understand their solutions or submit enquiries. This fragmentation across internal operations and external digital presence created inefficiency, delays, and reduced business growth, as the management could not rely on accurate data or attract leads effectively through the website.

Solution

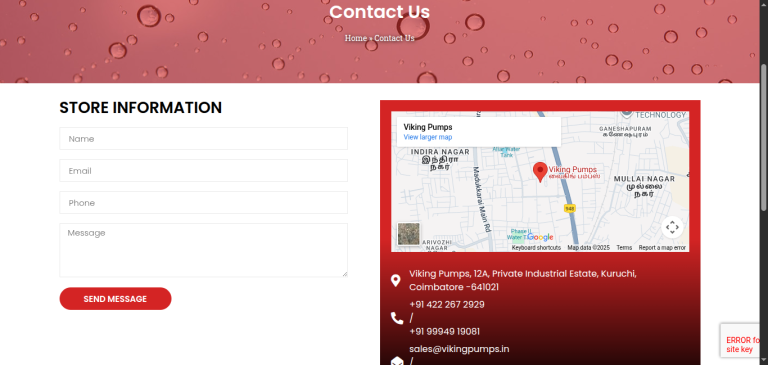

To streamline operations and strengthen the company’s digital presence, we implemented a centralized Odoo ERP system using Manufacturing, Inventory, Purchase, and Accounting modules, supported by custom production-costing and stock request/issue workflows for accurate traceability and real-time material tracking. Alongside ERP setup, the company website was redesigned with a modern interface, optimized product content, improved navigation, mobile responsiveness, and clear enquiry pathways to build credibility and increase conversions. This combined solution ensures accurate data flow, optimized production and inventory control, better costing insights, and a strong digital identity that supports lead generation and business growth.

Problem Statement

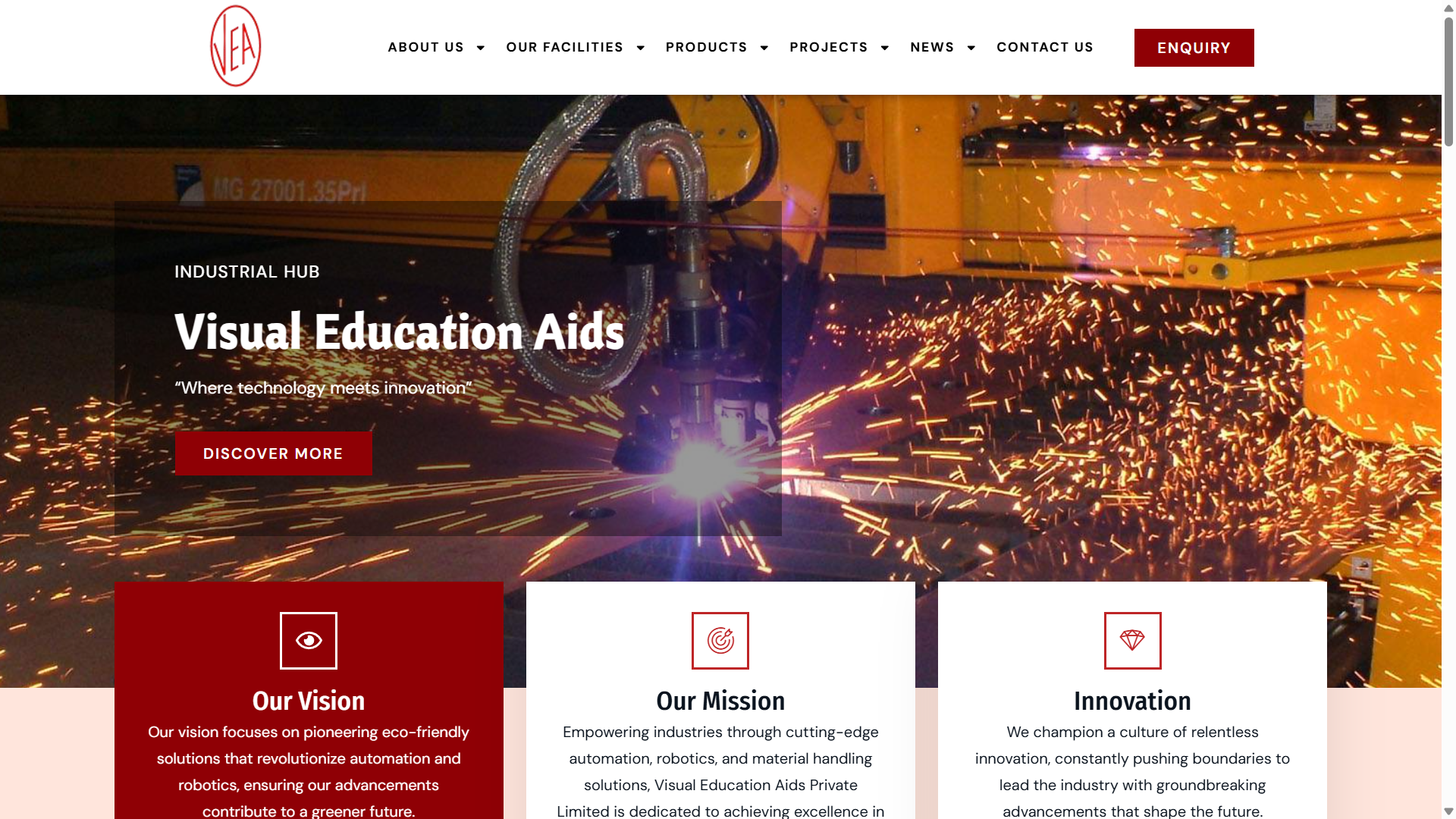

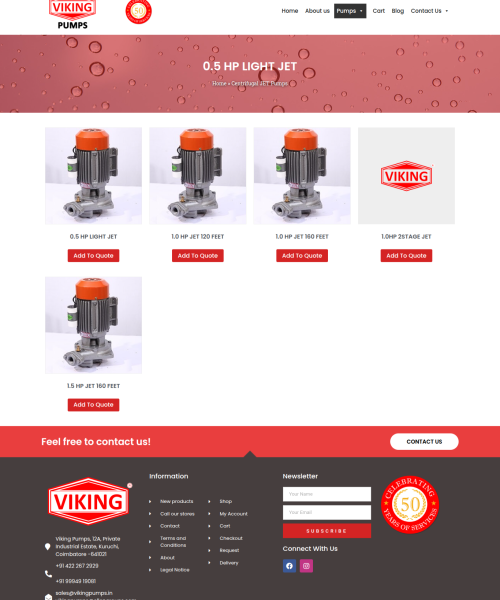

The current website contains essential product details, but several issues limit user engagement and search visibility:

- The website interface looks outdated and does not reflect a modern industrial brand image.

- Product information lacks structured formatting, making it harder for users to compare or understand features.

- No strong call-to-action areas to help convert visitors into sales enquiries.

- Limited visuals and technical diagrams, which reduces product clarity for engineers and procurement teams.

- Weak mobile responsiveness and inconsistent layout on different devices.

- Lack of trust-building elements such as certifications, client logos, applications, and industry success stories.

Solution

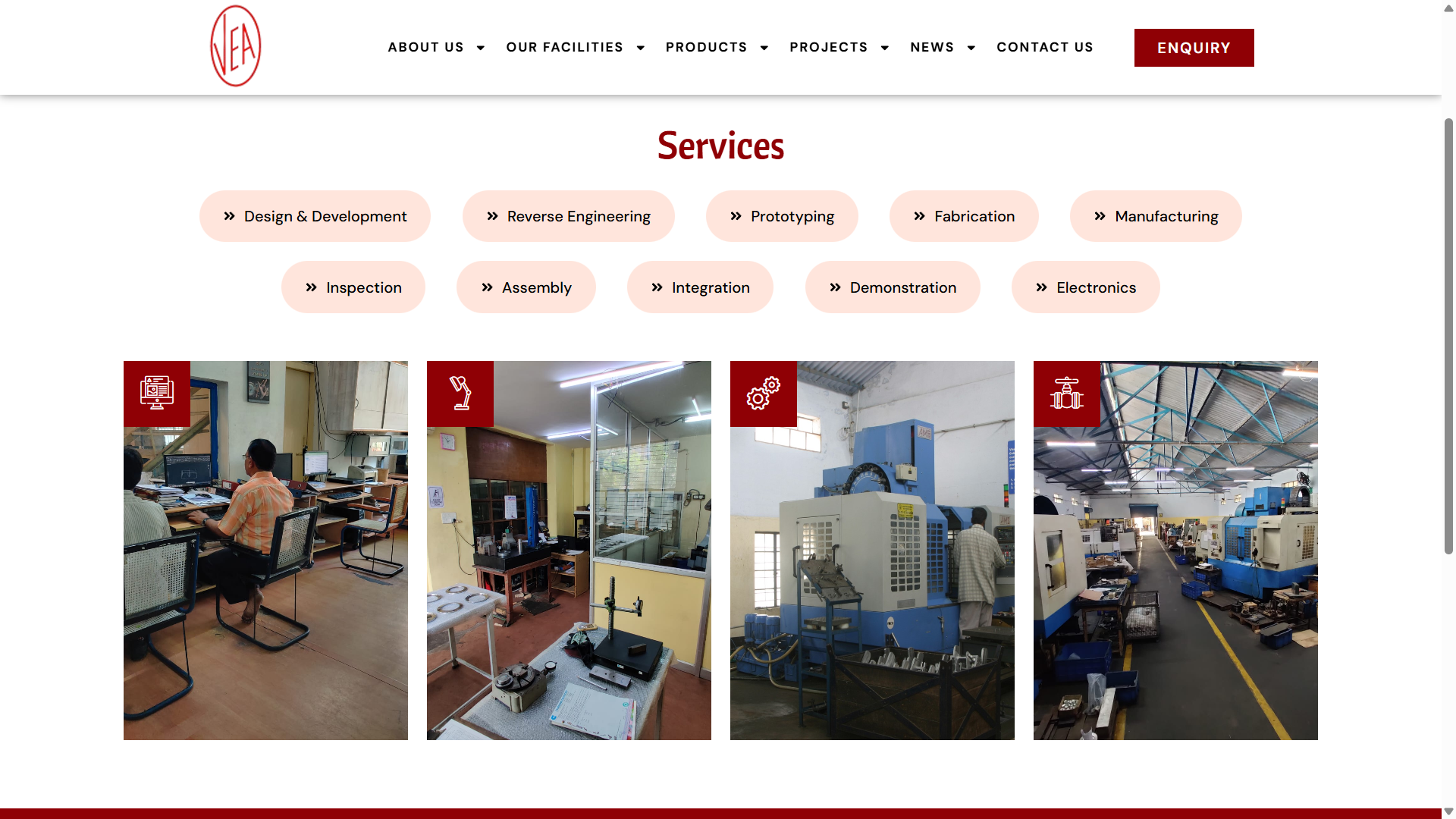

To strengthen Viking Pumps India’s digital presence, a modern and user-friendly website improvement strategy is recommended:

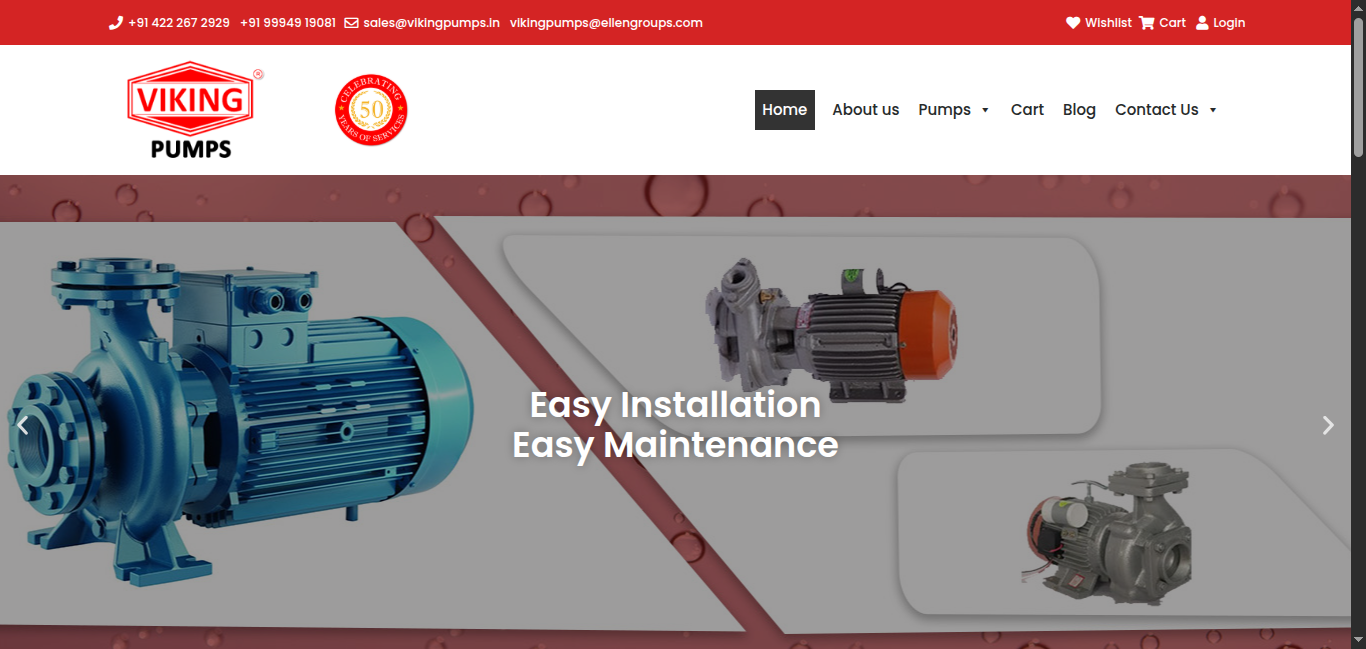

- Redesigning the website with a clean industrial layout, strong typography, and improved product presentation.

- Creating detailed, SEO-optimized product pages with features, applications, flow diagrams, and downloadable datasheets.

- Adding clear enquiry buttons, quotation request forms, and quick-contact options to increase conversions.

- Improving mobile responsiveness, image optimization, and overall page speed.

- Including trust-building sections such as industries served, certifications, client testimonials, and case studies.

- Adding product comparison tables and application-wise categorization for easy navigation.

Problem Statement

- Currently, operations rely on fragmented systems, manual records, spreadsheets or disconnected tools — leading to inconsistent data on inventory, material consumption, production costs, and stock movements.

- This fragmentation causes difficulty in tracking real material usage, inaccurate costing, delays in stock issue/requests, potential stockouts or overstock, and lack of visibility for management into real production cost, inventory levels, and profitability.

- Without an integrated system, it’s hard to coordinate manufacturing, procurement, inventory and accounting — resulting in inefficiency, waste, delayed decisions, and cost leakages.

Solution

- Implement Odoo’s default modules for Manufacturing, Inventory, Purchase, Accounting — to automate material procurement, work orders, stock movement, and financial operations — and add custom modules: a “production-costing” module to capture real material, labor, overhead costs per batch/product; and separate, streamlined forms/views for stock request and stock issue to formalize and track internal stock transfers.

- This will ensure real-time inventory tracking, accurate cost accounting, smooth stock issue/request workflows, and end-to-end traceability.

- With dashboards and reports, management can monitor production costs, inventory status, reorder needs, and profitability — enabling data-driven decisions, reduced waste, optimized material usage, and improved overall operational efficiency.